-

Khu công nghiệp Dalingshan Quảng Đông

How To Choose The Right Industrial Cooling Solution

Industrial Cooling Solutions For Your Guide

Nhiều loại khác nhau hệ thống làm mát công nghiệp có sẵn trên thị trường và giúp bạn xác định dung dịch làm mát là phù hợp với doanh nghiệp của bạn.

. Chúng tôi sẽ đi sâu vào chi tiết cụ thể của từng hệ thống, xem xét các yếu tố như hiệu quả năng lượng, chi phí và yêu cầu bảo trì. Cho dù bạn đang làm việc trong ngành nhựa, vận hành trung tâm dữ liệu hay quản lý nhà máy chế biến thực phẩm, hãy hiểu nhu cầu làm mát is crucial for optimal operation and productivity.

Mục lục

1. Các loại hệ thống làm mát công nghiệp chính là gì?

Hệ thống làm mát công nghiệp là cần thiết để duy trì nhiệt độ hoạt động tối ưu trong nhiều ngành công nghiệp khác nhau. Các hệ thống này được thiết kế để hấp thụ nhiệt từ thiết bị công nghiệp hoặc các quy trình, đảm bảo hoạt động trơn tru và hiệu quả.

- Hệ thống làm mát bằng không khí: Những hệ thống này sử dụng quạt và không khí để tản nhiệt. Chúng là lựa chọn phổ biến do tính đơn giản và hiệu quả về chi phí. Tuy nhiên, hiệu quả của chúng phụ thuộc vào nhiệt độ không khí xung quanh. Là nhà sản xuất hàng đầu, chúng tôi cung cấp máy làm lạnh trục vít làm mát bằng không khí cung cấp khả năng làm mát đáng tin cậy và hiệu quả cho nhiều ứng dụng khác nhau. Không khí hệ thống làm mát thường được sử dụng kết hợp với các phương pháp làm mát khác để nâng cao hiệu quả tổng thể.

Các công nghệ làm mát được sử dụng trong các hệ thống này đã tiến bộ đáng kể trong những năm gần đây. Hiện đại hệ thống làm mát cung cấp nâng cao hiệu quả năng lượng và kiểm soát nhiệt độ chính xác, làm cho chúng trở nên lý tưởng cho nhiều loại ứng dụng công nghiệp.

- Industrial cooling systems vary by heat transfer method:

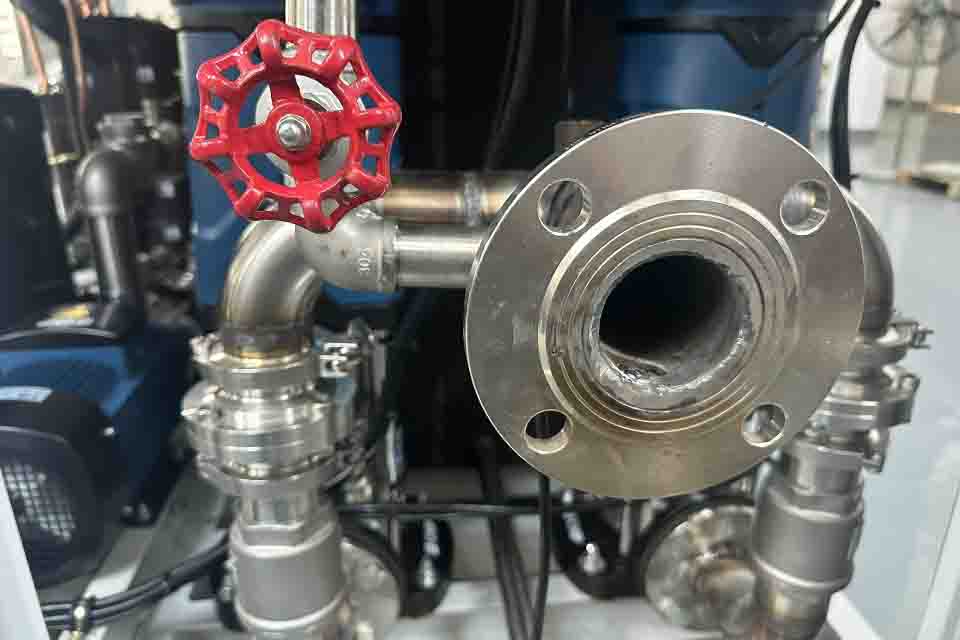

- Water Cooling: Cost-effective, using chilled water for rapid, reliable cooling.

- Dry Cooling: Uses air-cooled exchangers, preventing water loss but less efficient.

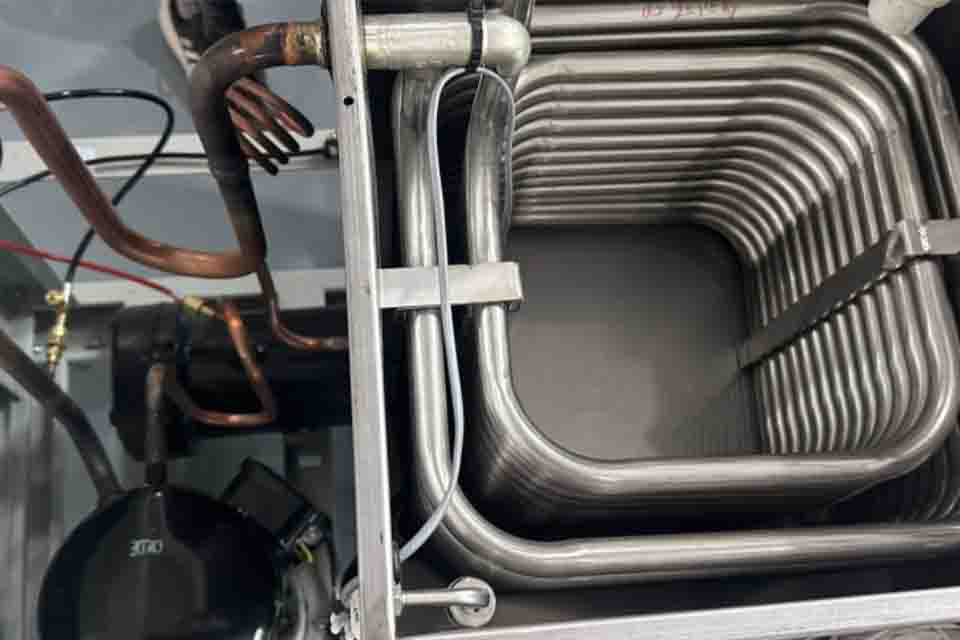

- Fluid Coil Cooling: Compact, customizable for refrigeration and water-saving needs.

- Các yếu tố cần xem xét

- No single system is ideal—efficiency depends on piping, recycling, and industry requirements. Cooling systems are vital for heavy industry, handling extreme temperatures with corrosion-resistant materials.

- Need a custom solution? Explore our packaged cooling systems & cooling towers Hôm nay!

2. How to Determine the Right Chiller for Your Business Needs?

Water Cooling vs. Dry Cooling vs. Fluid Coil Cooling: Key Differences

Industrial cooling systems vary by heat transfer method:

- Water Cooling: Cost-effective, using chilled water for rapid, reliable cooling.

- Dry Cooling: Uses air-cooled exchangers, preventing water loss but less efficient.

- Fluid Coil Cooling: Compact, customizable for refrigeration and water-saving needs.

Các yếu tố cần xem xét

No single system is ideal—efficiency depends on piping, recycling, and industry requirements. Cooling systems are vital for heavy industry, handling extreme temperatures with corrosion-resistant materials.

Need a custom solution? Explore our packaged cooling systems & cooling towers Hôm nay!

Consider the lượng nhiệt generated by your operations and specific yêu cầu làm mát. the ambient temperature of your facility, and any specific environmental regulations you need to comply with.

- Xác định nhu cầu làm mát của bạn: Bắt đầu bằng cách xác định tải nhiệt của thiết bị hoặc quy trình của bạn. Điều này sẽ giúp bạn chọn dung dịch làm mát với công suất phù hợp. Tham khảo ý kiến chuyên gia của chúng tôi để có được giải pháp làm mát công nghiệp phù hợp với yêu cầu của bạn. Chúng tôi có thể giúp bạn tìm hệ thống làm mát công nghiệp hoàn hảo giải pháp đáp ứng nhu cầu cụ thể của bạn.

- Đánh giá các lựa chọn của bạn: Một khi bạn hiểu được nhu cầu làm mát, nghiên cứu các loại khác nhau các loại hệ thống làm mát công nghiệp có sẵn. Xem xét các yếu tố như chi phí ban đầu, chi phí vận hành, yêu cầu bảo trì và tác động môi trường. Là nhà sản xuất máy làm lạnh nước công nghiệp, chúng tôi cung cấp nhiều lựa chọn khác nhau để phù hợp với các ngành công nghiệp và ứng dụng khác nhau. Chúng tôi cung cấp giải pháp làm mát lý tưởng bằng cách cân bằng hiệu suất, hiệu quả và hiệu quả về chi phí.

Lựa chọn hệ thống làm mát công nghiệp phù hợp Giải pháp rất quan trọng để đảm bảo hiệu quả và tuổi thọ của thiết bị. Nó cũng ảnh hưởng đến chi phí vận hành và năng suất chung của bạn. Tốt hơn hết là bạn nên tham khảo ý kiến của chuyên gia trong nhóm của chúng tôi.

3. Hệ thống làm mát bằng không khí có lợi ích gì?

Hệ thống làm mát bằng không khí là lựa chọn phổ biến cho nhiều ứng dụng công nghiệp do tính đơn giản, độ tin cậy và hiệu quả về chi phí. Chúng sử dụng quạt để lưu thông không khí xung quanh thiết bị, tản nhiệt và duy trì nhiệt độ hoạt động tối ưu.

- Sự đơn giản và độ tin cậy: Máy làm mát không khí có thiết kế tương đối đơn giản, có ít bộ phận chuyển động hơn so với các loại khác hệ thống làm mát. Sự đơn giản này chuyển thành độ tin cậy cao hơn và yêu cầu bảo trì thấp hơn. Là một nhà sản xuất hàng đầu, chúng tôi cung cấp một loạt máy làm mát không khí công nghiệp được thiết kế để có độ bền và hiệu suất lâu dài.

- Hiệu quả về chi phí: Hệ thống làm mát bằng không khí thường có chi phí trả trước thấp hơn so với thanh khoản hệ thống làm mát. Chúng cũng tiêu thụ ít năng lượng hơn trong nhiều trường hợp, dẫn đến chi phí vận hành thấp hơn. giải pháp làm mát tiết kiệm năng lượng được thiết kế để giảm thiểu mức tiêu thụ năng lượng mà không ảnh hưởng đến hiệu suất. Ví dụ, máy làm mát không khí công nghiệp cung cấp khả năng làm mát hiệu quả trong khi vẫn kiểm soát được chi phí năng lượng.

4. Tại sao nên cân nhắc làm mát bằng bay hơi cho các quy trình công nghiệp?

Làm mát bằng bay hơi là một điều tự nhiên và làm mát tiết kiệm năng lượng phương pháp đã được sử dụng trong nhiều thế kỷ. Nó hoạt động bằng cách làm bay hơi nước, hấp thụ nhiệt từ không khí xung quanh, tạo ra hiệu ứng làm mát.

- Hiệu quả năng lượng: Hệ thống làm mát bay hơi được biết đến với mức cao hiệu quả năng lượng. Chúng tiêu thụ ít năng lượng hơn đáng kể so với các hệ thống điều hòa không khí truyền thống, khiến chúng trở thành một lựa chọn thân thiện với môi trường. giải pháp làm mát kết hợp công nghệ làm mát bay hơi tiên tiến để tiết kiệm năng lượng tối đa.

- Làm mát hiệu quả: Làm mát bằng bay hơi có thể cung cấp làm mát hiệu quả trong nhiều bối cảnh công nghiệp khác nhau. Nó đặc biệt phù hợp với khí hậu nóng, khô, nhưng cũng có thể được sử dụng ở những khu vực ẩm ướt hơn với hệ thống thông gió thích hợp. Chuyên môn của chúng tôi về làm mát bay hơi cho phép chúng tôi thiết kế giải pháp tùy chỉnh ngay cả đối với những ứng dụng đòi hỏi khắt khe nhất. Nhóm của chúng tôi có thể cung cấp lời khuyên chuyên môn về tính phù hợp của một dung dịch làm mát.

5. Làm thế nào để chọn công nghệ làm mát phù hợp với nhu cầu cụ thể của bạn?

Lựa chọn công nghệ làm mát phù hợp cho bạn yêu cầu làm mát cụ thể bao gồm việc cân nhắc cẩn thận các yếu tố khác nhau. Bao gồm loại quá trình công nghiệp, tải nhiệt, nhiệt độ môi trường và bất kỳ cân nhắc nào về môi trường hoặc quy định.

- Đánh giá nhu cầu của bạn: Bắt đầu bằng cách đánh giá cụ thể của bạn nhu cầu làm mát. Hãy xem xét lượng nhiệt được tạo ra bởi thiết bị hoặc quy trình của bạn, cũng như phạm vi nhiệt độ hoạt động cần thiết. Là nhà sản xuất hàng đầu máy làm lạnh công nghiệp, chúng tôi cung cấp nhiều loại công nghệ và hệ thống làm mát có thể đáp ứng nhiều yêu cầu khác nhau.

- Tham khảo ý kiến chuyên gia: Lựa chọn đúng công nghệ có thể phức tạp. Tham khảo ý kiến của nhóm chuyên gia của chúng tôi có thể giúp bạn đưa ra quyết định sáng suốt. Chúng tôi có thể phân tích nhu cầu của bạn và đề xuất giải pháp phù hợp nhất dung dịch làm mát. Chúng tôi chuyên thiết kế giải pháp làm mát công nghiệp được thiết kế riêng theo nhu cầu cụ thể của ngành, chẳng hạn như tháp giải nhiệt.

6. Bạn cần biết những gì trước khi mua hệ thống làm mát công nghiệp?

Mua hệ thống làm mát công nghiệp là một khoản đầu tư đáng kể. Điều cần thiết là phải nghiên cứu kỹ lưỡng các lựa chọn của bạn và cân nhắc nhiều yếu tố khác nhau trước khi mua hàng.

- Công suất làm mát: Xác định yêu cầu công suất làm mát dựa trên tính toán tải nhiệt của bạn. Lựa chọn đúng đắn công suất là rất quan trọng cho hoạt động hiệu quả và hiệu suất. Là một nhà sản xuất máy làm lạnh nước công nghiệp, chúng tôi cung cấp nhiều mẫu mã với nhiều công suất khác nhau để phù hợp với các nhu cầu khác nhau.

- Hiệu quả năng lượng: Lựa chọn giải pháp làm mát tiết kiệm năng lượng để giảm chi phí hoạt động và giảm thiểu dấu chân môi trường của bạn. hệ thống làm mát được thiết kế chú trọng đến hiệu quả năng lượng, kết hợp các công nghệ tiên tiến để tối ưu hóa hiệu suất đồng thời giảm thiểu mức tiêu thụ năng lượng.

- Yêu cầu bảo trì: Hãy xem xét các yêu cầu bảo trì của hệ thống làm mát. Bảo trì thường xuyên là điều cần thiết để đảm bảo hiệu suất và tuổi thọ tối ưu. máy làm lạnh công nghiệp được thiết kế để dễ bảo trì, với các thành phần dễ tiếp cận và giao diện thân thiện với người dùng.

7. Hiệu quả năng lượng quan trọng như thế nào trong làm mát công nghiệp?

Hiệu quả năng lượng là một sự cân nhắc quan trọng trong làm mát công nghiệp. Nó ảnh hưởng trực tiếp đến chi phí hoạt động và tác động đến môi trường của bạn. Lựa chọn đúng đắn hệ thống tiết kiệm năng lượng có thể mang lại khoản tiết kiệm đáng kể về lâu dài.

- Tiết kiệm chi phí: Giải pháp làm mát tiết kiệm năng lượng tiêu thụ ít năng lượng hơn, dẫn đến hóa đơn tiền điện thấp hơn. hệ thống làm mát được thiết kế để tối ưu hóa việc sử dụng năng lượng, giúp bạn giảm chi phí vận hành.

- Tác động môi trường: Giảm mức tiêu thụ năng lượng cũng giúp giảm lượng khí thải carbon của bạn. Lựa chọn làm mát tiết kiệm năng lượng phù hợp với các mục tiêu phát triển bền vững và thể hiện trách nhiệm của công ty. Chúng tôi cam kết phát triển giải pháp làm mát để giảm thiểu tác động đến môi trường.

8. Giải pháp tùy chỉnh là gì và chúng có thể mang lại lợi ích gì cho doanh nghiệp của bạn?

Giải pháp tùy chỉnh được thiết kế riêng để đáp ứng nhu cầu cụ thể của doanh nghiệp bạn. Chúng có thể cung cấp hiệu suất, hiệu quả và độ tin cậy được cải thiện so với các giải pháp có sẵn. Nhóm của chúng tôi chuyên cung cấp các giải pháp tùy chỉnh hệ thống làm mát đáp ứng các yêu cầu riêng biệt của bạn.

- Hiệu suất được tối ưu hóa: Giải pháp tùy chỉnh được thiết kế để tối ưu hóa hiệu suất cho ứng dụng cụ thể của bạn. Điều này có thể dẫn đến hiệu quả được cải thiện, giảm thời gian chết và tăng năng suất. Chuyên môn của chúng tôi trong nhiều ngành công nghiệp khác nhau cho phép chúng tôi phát triển giải pháp phù hợp theo nhu cầu cụ thể của bạn.

- Tính linh hoạt và khả năng mở rộng: Giải pháp tùy chỉnh có thể được thiết kế để thích ứng với nhu cầu thay đổi của bạn. Cho dù bạn yêu cầu thêm công suất làm mát hoặc cần phải tích hợp hệ thống làm mát với các thiết bị khác, chúng tôi có thể cung cấp một giải pháp linh hoạt và có thể mở rộng. giải pháp làm mát được thiết kế để phát triển cùng doanh nghiệp của bạn.

9. Có những loại máy làm mát công nghiệp nào?

Máy làm mát công nghiệp có nhiều loại khác nhau, mỗi loại được thiết kế cho các ứng dụng và yêu cầu làm mát cụ thể. Hiểu được sự khác biệt giữa các loại này là điều cần thiết để lựa chọn đúng hệ thống phù hợp với nhu cầu của bạn.

- Máy làm lạnh bằng không khí: Những máy làm mát này sử dụng không khí xung quanh để tản nhiệt. Chúng thường nhỏ gọn hơn và dễ lắp đặt hơn so với máy làm mát bằng nước. máy làm lạnh bằng không khí được thiết kế để đạt hiệu quả và độ tin cậy, khiến chúng trở thành lựa chọn phổ biến cho nhiều ngành công nghiệp. Chúng tôi cũng cung cấp Máy làm lạnh Glycol phù hợp với nhiều ngành công nghiệp.

- Máy làm lạnh giải nhiệt bằng nước: Những máy làm mát này sử dụng nước làm môi trường làm mát. Chúng thường hiệu quả hơn máy làm mát bằng không khí, đặc biệt là trong môi trường nhiệt độ cao. máy làm lạnh giải nhiệt bằng nước được thiết kế để đạt hiệu suất tối đa và tiết kiệm năng lượng.

10. Những cân nhắc chính về làm mát công nghiệp trong môi trường thương mại và công nghiệp là gì?

Làm mát công nghiệp trong các bối cảnh thương mại và công nghiệp đòi hỏi phải lập kế hoạch cẩn thận và cân nhắc nhiều yếu tố khác nhau. hệ thống làm mát phải đáng tin cậy, hiệu quả và có khả năng đáp ứng các yêu cầu cụ thể của ứng dụng.

- Độ tin cậy: Người được chọn hệ thống làm mát đáng tin cậy và có khả năng hoạt động liên tục mà không bị hỏng hóc thường xuyên. Thời gian ngừng hoạt động có thể tốn kém trong các thiết lập công nghiệp, vì vậy độ tin cậy là tối quan trọng. máy làm lạnh công nghiệp được chế tạo để chịu được sự khắc nghiệt của hoạt động liên tục, đảm bảo thời gian hoạt động tối đa.

- Hiệu quả: Hiệu quả năng lượng rất quan trọng để giảm thiểu chi phí hoạt động. Lựa chọn giải pháp làm mát tiết kiệm năng lượng để giảm hóa đơn tiện ích và tác động đến môi trường của bạn. hệ thống làm mát kết hợp các công nghệ tiên tiến để tối ưu hóa việc sử dụng năng lượng. hiệu quả làm mát cũng rất quan trọng để duy trì năng suất.

Câu hỏi thường gặp:

Sự khác biệt giữa máy làm lạnh bằng không khí và máy làm lạnh bằng nước là gì?

Máy làm lạnh bằng không khí sử dụng không khí xung quanh để tản nhiệt, trong khi máy làm lạnh bằng nước sử dụng nước làm môi trường làm mát. Máy làm lạnh bằng nước thường hiệu quả hơn, đặc biệt là trong môi trường nhiệt độ cao.

Làm thế nào để xác định công suất làm mát phù hợp với nhu cầu của tôi?

Bạn cần tính toán tải nhiệt do thiết bị hoặc quy trình của bạn tạo ra. Điều này liên quan đến việc xem xét các yếu tố như mức tiêu thụ điện năng của thiết bị, phạm vi nhiệt độ hoạt động và nhiệt độ môi trường xung quanh cơ sở của bạn.

Lợi ích của việc sử dụng giải pháp làm mát tùy chỉnh là gì?

Giải pháp tùy chỉnh được thiết kế riêng theo nhu cầu cụ thể của bạn, cung cấp hiệu suất được tối ưu hóa, hiệu quả nâng cao và độ tin cậy cao hơn. Chúng cũng có thể được thiết kế để thích ứng với các yêu cầu thay đổi của bạn, mang lại sự linh hoạt và khả năng mở rộng.

Hiệu quả năng lượng quan trọng như thế nào trong làm mát công nghiệp?

Hiệu quả năng lượng rất quan trọng để giảm thiểu chi phí vận hành và giảm tác động đến môi trường. Giải pháp làm mát tiết kiệm năng lượng tiêu thụ ít năng lượng hơn, dẫn đến hóa đơn tiền điện thấp hơn và lượng khí thải carbon nhỏ hơn.

Tại sao hệ thống làm mát phù hợp lại quan trọng đối với các quy trình công nghiệp?

Quy trình công nghiệp tạo ra nhiệt lượng đáng kể. Làm mát thích hợp là điều cần thiết để duy trì nhiệt độ hoạt động tối ưu, ngăn ngừa hư hỏng thiết bị và đảm bảo chất lượng sản phẩm.

Hệ thống làm mát công nghiệp cần bảo trì những gì?

Bảo trì thường xuyên là điều cần thiết để đảm bảo hiệu suất và tuổi thọ tối ưu của hệ thống làm mát công nghiệp. Bao gồm các nhiệm vụ như vệ sinh bộ lọc, kiểm tra mức chất làm lạnh và kiểm tra các bộ phận xem có bị hao mòn không.

Phần kết luận:

- Lựa chọn giải pháp làm mát công nghiệp phù hợp là điều cần thiết để duy trì nhiệt độ hoạt động tối ưu, đảm bảo hiệu quả và tối đa hóa năng suất.

- Có nhiều loại các loại hệ thống làm mát công nghiệp có sẵn, bao gồm cả không khí hệ thống làm mát, chất lỏng hệ thống làm mátvà bốc hơi hệ thống làm mát.

- Tìm sự phù hợp phù hợp cho bạn nhu cầu kinh doanh bao gồm việc đánh giá cẩn thận các thông tin cụ thể của bạn yêu cầu làm mát và đánh giá các lựa chọn khác nhau có sẵn.

- Hiệu quả năng lượng là một sự cân nhắc quan trọng trong làm mát công nghiệpvì nó ảnh hưởng trực tiếp đến chi phí hoạt động và tác động đến môi trường của bạn.

- Giải pháp tùy chỉnh có thể cung cấp hiệu suất, hiệu quả và độ tin cậy cao hơn so với các giải pháp có sẵn.

- Bảo trì thường xuyên là điều cần thiết để đảm bảo hiệu suất và tuổi thọ tối ưu của hệ thống làm mát công nghiệp.

- Tham khảo ý kiến của các chuyên gia có thể giúp bạn đưa ra quyết định sáng suốt và lựa chọn phù hợp nhất dung dịch làm mát cho nhu cầu của bạn.

- Người được chọn hệ thống làm mát đáng tin cậy, hiệu quả và có khả năng đáp ứng các nhu cầu cụ thể của ứng dụng của bạn.

- Của chúng tôi máy làm lạnh công nghiệp được thiết kế để có độ bền cao, dễ bảo trì và hiệu suất tối đa.

- Chúng tôi cam kết phát triển giải pháp làm mát giúp giảm thiểu tác động đến môi trường và giúp bạn đạt được mục tiêu phát triển bền vững.

Bằng cách hiểu các loại khác nhau hệ thống làm mát công nghiệp và xem xét các yếu tố được thảo luận trong bài viết này, bạn có thể đưa ra quyết định sáng suốt và lựa chọn giải pháp làm mát phù hợp cho doanh nghiệp của bạn.

Remember, the hệ thống làm mát bên phải có thể tác động đáng kể đến hiệu quả hoạt động, năng suất và thành công chung của bạn. Là nhà sản xuất hàng đầu máy làm lạnh nước công nghiệp, we are here to help you every step of the way.

Contact us today to learn more about our giải pháp làm mát và cách chúng tôi có thể giúp bạn tìm được sự phù hợp hoàn hảo cho nhu cầu của bạn. Chúng tôi tận tâm cung cấp giải pháp làm mát vượt trội đáp ứng các yêu cầu riêng biệt của nhiều ngành công nghiệp khác nhau, bao gồm Ngành công nghiệp nhựa và cao su, Ngành công nghiệp gia công, Ngành công nghiệp thực phẩm và đồ uống, Ngành công nghiệp hóa chất và dược phẩm, Ngành công nghiệp điện tử, Ngành công nghiệp laser, Ngành công nghiệp in ấn, Ngành công nghiệp y tế, Phòng thí nghiệm và Viện nghiên cứu và Trung tâm dữ liệu.

Của chúng tôi máy làm lạnh chống nổ được thiết kế đặc biệt cho các ngành công nghiệp có yêu cầu an toàn nghiêm ngặt. Đối với các ứng dụng đòi hỏi khắt khe hơn, máy làm lạnh trung tâm trục vít làm mát bằng nước cung cấp hiệu suất làm mát đặc biệt. Ngoài ra, bộ trao đổi nhiệt vỏ và ống cung cấp các giải pháp truyền nhiệt hiệu quả. Cuối cùng, máy làm lạnh sữa hoàn hảo cho ngành thực phẩm và đồ uống, đảm bảo chất lượng và an toàn sản phẩm.