-

Dalingshan Industrial Guangdong

HVAC Chillers

🕢 [ Füllen Sie das Formular aus und wir werden innerhalb von 30 Minuten antworten!]

Advanced HVAC Chiller Solutions for Optimal Performance

In today’s demanding industrial and commercial environments, reliable and efficient cooling is not just a luxury—it’s a necessity. As a leading manufacturer of HVAC chillers, we understand the critical role these systems play in ensuring smooth operations, from maintaining precise temperatures in plastic manufacturing to providing comfortable environments in hospitals and office buildings. Our commitment is to deliver high-quality, custom-engineered chiller solutions that meet the unique needs of diverse industries. We are dedicated to excellence and continuous innovation, helping our customers achieve peak performance and energy efficiency. This article will explore our capabilities and the benefits of partnering with us for your cooling needs.

We focus on understanding the unique challenges our clients face and designing Kältesysteme that provide optimum performance and longevity through the basics of chillers. Our expertise allows us to tailor solutions that are not only effective but also energy-efficient and cost-effective. Our systems are designed to ensure that temperature fluctuations are minimized and the environment is consistent.

We invite you to reach out and discuss how our specialized chillers can enhance your operations. We are not just manufacturers; we are your partners in creating the ideal environment for success. Whether you require a basic chiller setup or a complex industrial solution, we have the expertise and experience to deliver.

Custom-Engineered Solutions: Meeting Your Specific Needs

We pride ourselves on providing custom-engineered solutions that cater to the exact needs of our clients. We recognize that every industry has unique cooling requirements. For example, plastic manufacturing plants need precise temperature control to prevent product defects, while supermarkets and hypermarkets must ensure the freshness of their perishables. Our chillers are designed to provide consistent, reliable cooling for any type of chiller application. We work closely with our clients to understand their processes and develop a cooling system that fits seamlessly into their operations.

Our engineering team utilizes the latest technologies and software to design chillers that meet specific cooling loads, environmental conditions, and operational requirements. We don’t believe in one-size-fits-all solutions, and we’re committed to developing Kältemaschinen that not only perform efficiently but also provide long-term value to our customers. Whether it’s a unique physical space, special cooling requirements, or strict energy standards, we have the expertise to customize our solutions and ensure your specific needs are met.

Advanced Technologies for Enhanced Performance and Efficiency

Our commitment to innovation is reflected in our use of advanced technologies. From high-efficiency compressors to smart control systems, we integrate the latest advancements to ensure our chillers provide superior performance and energy efficiency. Our chillers are designed for precise temperature control, minimizing fluctuations and maintaining optimal conditions for your chilled water operations. We understand that energy costs can significantly impact your bottom line. Therefore, we focus on optimizing every aspect of our chiller designs to maximize energy savings and reduce operating expenses.

We utilize state-of-the-art refrigerant technologies and robust control systems to achieve superior performance and energy savings. Our Kältesysteme are also designed to minimize their environmental impact. We adhere to the latest industry standards and regulations, ensuring that our products are both effective and environmentally friendly in the water system. By choosing our chillers, you are investing in a solution that is engineered for long-term value and sustainability.

Comprehensive Support and Maintenance for Long-Term Reliability

We are dedicated to providing comprehensive support and Wartung services to ensure the long-term reliability of our chiller systems. We understand that downtime can have a detrimental impact on your operations, and our goal is to provide proactive and responsive support to keep your system running smoothly. Our team of skilled technicians is available to conduct regular inspections, perform maintenance, and provide any necessary repairs. With our service plan, we ensure that your cooling system will consistently deliver the performance it was designed to do.

We offer flexible maintenance programs that are tailored to meet your specific needs. Whether you require routine check-ups, emergency repairs, or full system upgrades, our team is equipped to handle any challenge. We also provide training and support for your in-house staff, ensuring they understand the operation and maintenance requirements of our chiller systems. Our commitment to customer satisfaction goes beyond the initial purchase. We are your long-term partners, dedicated to providing the highest level of support and service to protect your investment and ensure your operations run smoothly.

Key Features of Our Chiller Systems:

- Custom-engineered to meet specific requirements

- Advanced technology for superior efficiency

- High-quality components for durability

- Precise temperature control

- Energy-efficient designs

- Environmental friendly water chiller

- Comprehensive maintenance programs

- 24/7 customer support

As HVAC chiller manufacturers, we are fully aware of the critical role our products play in maintaining your operations. From industrial processes to comfort conditioning, we’re committed to delivering high-performance, reliable chillers that meet your needs. Our understanding of industrial requirements enables us to custom design systems for the plastic industry, commercial buildings, supermarkets, hypermarkets, printing equipment, laser cutting machines, medical devices, hospitals, and office buildings.

Contact us to learn more about how our systems can improve your efficiency and reliability. We take great pride in our customized solutions and look forward to helping you meet your cooling requirements.

Chiller Advantages: Understanding the basics of chillers. Tailored, efficient, reliable components of a chiller. Contact us for top-tier HVAC chiller solutions and expert service!

Use code with caution. Html

Optimizing Your Operations with Advanced HVAC Chiller Solutions

In the complex landscape of modern commercial and industrial operations, the significance of an effective HVAC system cannot be overstated. At the heart of these systems often lies a chiller, a vital component responsible for maintaining precise temperature control across a variety of applications. From the plastics industry where product consistency depends on stable cooling to hospitals and medical facilities where patient well-being is paramount, chillers play a critical role. This article delves into the world of HVAC chillers, exploring the various types, their applications, and the crucial factors that contribute to their effective operation and maintenance. We’ll also touch on how our expertise as manufacturers can help you find the perfect solution for your needs.

What are the Primary Applications of HVAC Chillers?

HVAC chillers are used in a wide range of applications, each requiring precise temperature control for optimal performance. In the plastic industry, chillers cool machinery and molds to ensure consistent product quality and prevent overheating. Supermarkets and hypermarkets utilize chillers to maintain the cold chain for perishable goods, preventing spoilage and waste. In the medical sector, chillers are crucial for regulating temperatures in operating rooms, MRI suites, and laboratories, providing a controlled environment for sensitive procedures.

Commercial buildings, office complexes, and educational facilities rely on chillers for air conditioning, ensuring a comfortable environment for occupants. Furthermore, chillers are essential in the printing and laser cutting industries, where they manage the heat generated by machinery. They are also used in data centers to prevent servers from overheating. These diverse applications highlight the essential role that chillers play in various industries.

How Do Air-Cooled Chillers Differ From Water-Cooled Systems?

The fundamental difference between air-cooled and water-cooled chillers are essential for efficient commercial HVAC systems. chillers is the method they use to reject heat. Air-cooled chillers use ambient air to cool the refrigerant, making them simpler to install and less costly for setup. They are often more suitable for smaller facilities with lower cooling loads or where water supply is limited. However, their energy efficiency can be affected by the ambient air temperature, with reduced performance on hot days in a chilled water system.

Water-cooled chillers use water to transfer heat, typically through a cooling tower or water source. They generally offer higher energy efficiency, especially in hotter climates, and are ideal for larger facilities with substantial cooling requirements. However, they require additional infrastructure for water handling, leading to higher initial investment and more complex maintenance.

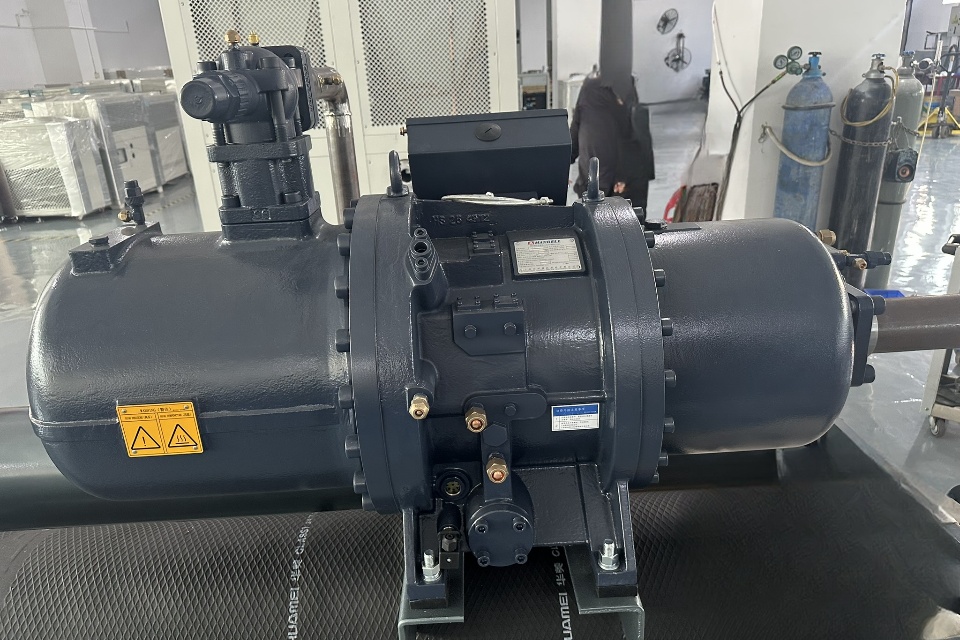

What Role Does the Compressor Play in a Chiller System?

Die compressor is the heart of the chiller, responsible for compressing the refrigerant and increasing its temperature and pressure. The compressor draws the low-pressure refrigerant vapor from the evaporator and compresses it into a high-pressure gas. This compression is essential for the refrigerant cycle, as it enables the refrigerant to release heat in the condenser. Without the compressor, the refrigeration cycle would not be possible in any type of chiller.

There are various types of compressors used in chillers, including scroll, screw, and centrifugal. Each type has its own benefits and is selected based on the specific requirements of the application. The compressor’s efficiency and reliability are essential for the overall performance and energy efficiency of the chiller system. Proper maintenance of this part will help maintain efficiency.

How Does the Evaporator and Condenser Function in the System?

The evaporator and condenser are two key components in the chiller system that work together to facilitate heat transfer. The evaporator is where the refrigerant absorbs heat from the chilled water, causing it to cool down. The refrigerant enters the evaporator as a low-pressure liquid and changes into a vapor as it absorbs heat from the chilled water, resulting in the cooling of the water being circulated in the system.

The condenser, on the other hand, is where the refrigerant releases heat. The hot, high-pressure refrigerant vapor from the compressor enters the condenser and is cooled. It transfers its heat to either ambient air (in air-cooled chillers) or a water source (in wassergekühlte Kältemaschinen). The refrigerant then condenses back into a liquid, ready to repeat the cycle. The efficient functioning of the evaporator and condenser is vital for optimal heat transfer and overall chiller performance in commercial HVAC systems.

What is the Role of Refrigerant in the Cooling Process?

Die refrigerant is the working fluid that enables the entire refrigeration cycle. It undergoes phase changes, alternating between liquid and vapor, while absorbing and releasing heat. The refrigerant flows through the closed-loop system, collecting heat from the water in the evaporator and releasing it in the condenser. The refrigerant’s properties determine its effectiveness, and the selection is critical for both cooling capacity and environmental impact.

There are various types of refrigerants, and the choice depends on regulations, energy goals, and specific chiller requirements. Modern refrigerants are designed to minimize environmental impact while maintaining high efficiency. Understanding the properties of the refrigerant used in your chiller is crucial for ensuring efficient and reliable cooling.

How Can You Optimize Energy Efficiency of a Chiller System?

Optimizing energy efficiency in a chiller system requires a comprehensive approach, starting with proper sizing and selection. A correctly sized chiller will operate more efficiently than an oversized unit that cycles on and off unnecessarily. Regular maintenance, including cleaning condenser and evaporator coils, is crucial for maintaining peak performance.

Other strategies include optimizing the water flow rate, implementing advanced control systems, and using free cooling options when conditions allow. Upgrading to more energy-efficient compressors, variable speed drives, and modern controls can significantly reduce energy consumption and operating costs. By focusing on these factors, businesses can achieve significant energy savings and reduce their environmental impact.

Why is Regular Maintenance Critical for Chiller Lifespan?

Regular maintenance is vital for extending the lifespan and maintaining the efficiency of a chiller. Neglecting maintenance can lead to decreased performance, increased energy consumption, and potential breakdowns. Maintenance includes checking refrigerant levels, cleaning coils, lubricating moving parts, verifying controls, and addressing any leaks or issues.

Proper maintenance not only ensures the reliability of the chiller but also reduces operating costs by ensuring that the system runs efficiently. A well-maintained chiller will also provide a more comfortable and safe environment, contributing to overall operational success in commercial HVAC applications. Maintenance should be done regularly by qualified technicians to make sure that the system performs correctly and efficiently.

What Factors Should You Consider When Choosing a Chiller?

Selecting the right chiller for your specific needs requires careful consideration of several factors. These include the size and layout of the facility, the cooling requirements, ambient temperature, and the available resources. For instance, smaller commercial spaces often do well with air-cooled chillers, while larger industrial facilities may be more suited for wassergekühlt systems.

Budget constraints, energy efficiency targets, and maintenance requirements are also important factors to consider. It’s crucial to select a chiller that meets your specific needs, offers long-term reliability, and fits within your budget. Consulting with a knowledgeable HVAC professional will help you make the best choice for your business, ensuring optimal performance and energy efficiency.

How Can Advanced Controls Improve Chiller Operations?

Advanced control systems play a crucial role in optimizing chiller operations. Smart controls can monitor and adjust the chiller’s performance in real time, ensuring efficient cooling while minimizing energy consumption. These systems can regulate refrigerant flow, water flow, and compressor speeds, adapting to fluctuating cooling needs and environmental conditions. Modern controls provide valuable insights into the performance of the system.

Implementing advanced control systems not only enhances efficiency but also provides valuable data for system optimization and predictive maintenance. These technologies help businesses maximize the effectiveness of their Kältesysteme, reduce operating costs, and maintain consistent comfort levels. This will allow you to get the most out of your investment for businesses in the long run.

What are the Common Challenges with HVAC Chiller Systems?

There are several common challenges associated with HVAC chiller systems , such as inadequate maintenance, refrigerant leaks, compressor issues, and fouling of heat transfer surfaces. These challenges can result in reduced efficiency, increased energy consumption, and costly breakdowns. Proper system maintenance and prompt attention to issues are vital to minimize problems.

Another common issue is incorrect installation or sizing, which can lead to decreased performance. Understanding these potential problems allows business owners to create plans to minimize them and improve overall performance. Proper installation and selection of the right equipment are important factors when starting out with a system.

Chiller Advantages: Precision cooling, maximized efficiency, reduced downtime. Partner with us for superior HVAC chillers!

Hilfe-Center

Haben Sie eine Frage? Bitte prüfen Sie diese Frage und Antworten

Water Chiller sind wie folgt:

- Entwerfen Sie eine gut kontrollierte Bewertungsroutine für Ihre Kältemaschine, um die Leistung im Laufe der Zeit genau zu überprüfen.

- Überprüfen Sie die Spulen und Rohrleitungen regelmäßig auf die Ansammlung von Staub, Kalzium- oder Magnesiumionen oder Ablagerungen, um diese rechtzeitig zu entfernen, damit keine Verstopfung entsteht.

- Halten Sie die Kältemittelfüllung stets aufrecht und lassen Sie sie nicht absinken, da dies die Leistung um 5-10% senkt.

- Routinemäßige Wartung und Instandhaltung zur Untersuchung der Kondensatorspulen auf verstopfte und freie Luftabschnitte.

- Kontrollieren Sie alle schädigenden Stoffe, und wenn Sie einen Schaden feststellen, lassen Sie ihn so schnell wie möglich beheben, damit er keine langfristigen Folgen hat.

- Sorgen Sie für eine gute Wasserversorgung, und verwenden Sie am besten gekühltes Wasser.