-

Dalingshan Industrial Guangdong

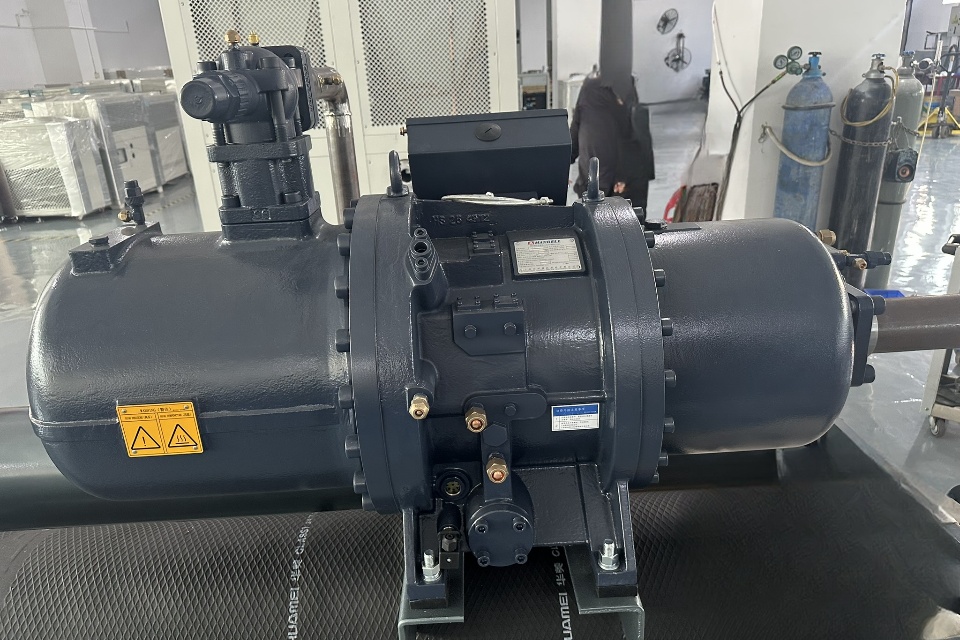

Anti-Explosion Chillers

Cooling capacity ranges from 5 Ton-200 Ton,

Temperature control ranges from -25°C to 30°C,

Top branded efficient scroll/screw compressor,

Thermostatic expansion valves, SS water tank,

Finned tube & external rotor fan for the condenser,

Rugged and duty design with double skin body,

Isolated electrical components & enclosed motor,

Warranty time up to 24 months after purchase.

🕢 [ Füllen Sie das Formular aus und wir werden innerhalb von 30 Minuten antworten!]

Reliable And Certified Professional Anti-Explosion Chillers

Are you operating in a hazardous process that requires specialized cooling solutions? hazardous environment where reliable and safe Kühlung Is cooling capacity critical for your operation in a hazardous process? Our The explosion-proof equipment is designed to withstand hazardous processes. Our water chillers are designed to handle hazardous processes efficiently. are engineered to provide dependable Kühlung while minimizing the risk of explosions. We are a leading chiller manufacturer, specializing in providing solutions for various industries, including chemical processing, oil and gas, pharmaceuticals, and other settings with flammable materials. Our Our explosion-proof chiller is equipped with advanced safety features.s are designed with multiple safety features and are built to comply with stringent industry safety standards. We understand that safety and Kühlung are of the upmost importance to your facility. We offer solutions for your most challenging environments and do not provide retail sales. Contact us today to learn more about how our expertise in hazardous process chiller manufacturing can benefit you. explosion-proof Kältemaschinen can ensure the safety and efficiency of your operations.

The Importance of Explosion-Proof Chillers in Hazardous Applications

Explosion-proof chillers are crucial for maintaining safe operating conditions in environments where flammable gases, liquids, or dust are present. These specialized Kältemaschinen are designed to prevent internal sparks or heat from triggering an external explosion. Standard Kältemaschinen can be a safety hazard in such conditions, as electrical components and the compressor can create ignition sources. Our explosion-proof chiller designs prevent this. They feature robust construction and sophisticated safety measures to minimize the risk of ignition. We are a proof chiller manufacturer and supplier who design our products to protect your people and your facility, and to provide the most reliable and safest Kühlung solution available. We provide a range of products from basic chiller units to more complex process specific equipment.

Our commitment to quality and safety is evident in every aspect of our explosion proof chiller design and construction. From the selection of materials to the advanced control systems, every detail is carefully considered to ensure the highest level of protection. In addition to the critical safety features, our explosion proof chillers also provide reliable and efficient KühlungOur chillers meet the demanding requirements of hazardous process applications. hazardous environments. Whether you need a chiller for air conditioning in a control room or for Prozesskühlung in a manufacturing facility, our explosion-proof Kältemaschinen offer the perfect solution. We make proof chillers for your application.

Advanced Features and Technologies in Our Explosion-Proof Chillers

Our explosion-proof chillers are designed with cutting-edge technology and high-quality materials to ensure safety, durability and superior performance. The compressor is protected using compressor inner protection, and each chiller is equipped with explosion-proof electrical components which are housed in an explosion-proof cabinet. This also includes explosion proof fan motors that have been specifically designed for hazardous environments. These designs ensure that no external source of ignition is present, particularly in hazardous processes. The evaporator is typically a shell and tube design, which is known for its efficient heat transfer capabilities, especially in explosion-proof chillers. Our chillers also include low level coolant protection and flow rate protection as additional safety measures to minimize the risks of an explosion. These features also protect the chiller unit from damage.

Unser explosion proof chillers are available in a range of capacities, to accommodate various Kühlung needs. We also offer both air cooled und water cooled We offer a range of chiller models, including those with low level coolant protection.Our chillers are designed to meet various cooling capacity requirements, depending on the specific requirements of the application. In addition to the safety features, our Kältemaschinen also include advanced control systems for precise temperature control and monitoring. Our design incorporates both overheat protection und exhaust overheat protection. We also provide anti freezing protection to protect the chiller unit from damage in colder environments. All our explosion proof chillers are manufactured in accordance with the highest industry standards. Our systems are also designed for easy integration into your existing cooling system. We are experts in making explosion proof chillers that you can trust. We are a reliable explosion proof chiller manufacturer.

Why Choose Our Explosion-Proof Chillers?

When selecting an explosion-proof chiller, it is essential to choose a reputable chiller manufacturer with expertise in this specialized field. We are a process chiller manufacturer and supplier who has a proven track record for providing high-quality explosion-proof Kältemaschinen. Our Kältemaschinen are designed and manufactured in compliance with the highest international standards, and we are known for delivering products that provide reliable and consistent performance. With a strong focus on safety, quality, and customization, we are your best partner for all your explosion-proof Kühlung needs. Our commitment is to provide not just equipment, but comprehensive solutions that meet the challenges of operating in hazardous areas. We are committed to finding the right explosion proof chiller for you.

Our team of experienced engineers will work closely with you to determine the best solution for your application, ensuring that all safety requirements are met. We consider every facet of your application, to deliver a product that is safe and effective. We offer detailed consultations, proof chiller requirement communication, custom chiller designs, and comprehensive installation and support services. Choosing our products will not only enhance safety but also improve the efficiency and reliability of your operations. We are a professional explosion proof chiller manufacturer. Our commitment to innovation and excellence makes us a clear choice for all your explosion-proof cooling requirements. We have a rich experience of making explosion proof chillers for your industrial applications, and also have a deep understanding of all proof chillers related safety measures. We will help you work out the correct explosion proof chiller suitable for your needs, and will make sure all explosion proof chiller designs are to code. We also provide long term support for our systems. We know that explosion proof chillers will save you time and money in the long run.

We provide solutions for many industries including:

- Industrielle Kältemaschinen

- Cooling Projects

- Commercial Facilities

- Pharmaceutical Clean Room

- Chemical Industry

- Plastic Injection & Extruding Industry

- Artificial Real Ice Rink Projects

- Environmental Simulation Laboratory

- Computer Server Room

- Telecommunications Stations

- Food and Beverage Processing Cooling

- Cold Storage Room

- Die Casting

- Rubber

- Printing

- And many other industries

Benefits of our explosion-proof chillers:

- Enhanced safety in hazardous environments

- Compliance with industry standards

- High-quality, durable construction

- Reliable and efficient operation

- Customizable solutions for various applications

- Comprehensive support and service

“Our new explosion-proof chiller has provided us with the reliability and safety we need in our chemical processing facility. The chiller is very well-built, and the customer service was excellent. I highly recommend their products” says a satisfied customer from the chemical processing industry.

Ready to ensure the safety of your explosion-proof electrical systems. hazardous environment? Kontakt today for a consultation and learn how our explosion-proof chillers can benefit your facility. We are a professional explosion proof chiller manufacturer.

Additional Technical Information

- Unser Kältemaschinen are designed for use with multiple refrigeration options.

- Unser Kältemaschinen use shell and tube heat exchangers.

- Our designs incorporate multiple safety controls, including flow rate protection.

- Unser Kältemaschinen also offer options for low-temperature chilled water operation.

- Our team can provide customized solutions that meet the specific requirements of your environment.

- We offer comprehensive installation and maintenance services for all our chiller models.

Internal Links

Explore our range of industrial chillers for electroplating or our industrial chillers for the textile industry. For other types of cooling, see our pages on water cooled screw chillers und air cooled screw chillers. If you require central systems, consider our water cooled screw central chillers. Also view our page for HVAC chillers.

Hilfe-Center

Haben Sie eine Frage? Bitte prüfen Sie diese Frage und Antworten

Water Chiller sind wie folgt:

- Entwerfen Sie eine gut kontrollierte Bewertungsroutine für Ihre Kältemaschine, um die Leistung im Laufe der Zeit genau zu überprüfen.

- Überprüfen Sie die Spulen und Rohrleitungen regelmäßig auf die Ansammlung von Staub, Kalzium- oder Magnesiumionen oder Ablagerungen, um diese rechtzeitig zu entfernen, damit keine Verstopfung entsteht.

- Halten Sie die Kältemittelfüllung stets aufrecht und lassen Sie sie nicht absinken, da dies die Leistung um 5-10% senkt.

- Routinemäßige Wartung und Instandhaltung zur Untersuchung der Kondensatorspulen auf verstopfte und freie Luftabschnitte.

- Kontrollieren Sie alle schädigenden Stoffe, und wenn Sie einen Schaden feststellen, lassen Sie ihn so schnell wie möglich beheben, damit er keine langfristigen Folgen hat.

- Sorgen Sie für eine gute Wasserversorgung, und verwenden Sie am besten gekühltes Wasser.