-

ডালিংশান ইন্ডাস্ট্রিয়াল গুয়াংডং

ওয়াটার কুলড স্ক্রোল ওয়াটার চিলার প্রস্তুতকারক

🕢 [ফর্মটি পূরণ করুন এবং আমরা ৩০ মিনিটের মধ্যে উত্তর দেব! ]

শিল্প চিলার: উৎপাদন কারখানার জন্য প্রয়োজনীয় শীতল সমাধান

উৎপাদন জগতে, সুনির্দিষ্ট তাপমাত্রা নিয়ন্ত্রণ কেবল বিলাসিতা নয় - এটি একটি প্রয়োজনীয়তা। আপনি শিল্প প্রক্রিয়াকরণ, পণ্য উৎপাদন, বা অন্য কোনও ধরণের বৃহৎ উৎপাদনের সাথে জড়িত থাকুন না কেন, সর্বোত্তম তাপমাত্রা নিশ্চিত করা আপনার ক্রিয়াকলাপের গুণমান, দক্ষতা এবং নির্ভরযোগ্যতার জন্য অত্যাবশ্যক। শিল্প চিলারগুলি এখানেই আসে। আপনার প্রক্রিয়া সরঞ্জামের জন্য শীতলকরণের নিখুঁত ভারসাম্য বজায় রাখার জন্য ডিজাইন করা, শিল্প চিলারগুলি বিভিন্ন শিল্পে তাপমাত্রা নিয়ন্ত্রণ ব্যবস্থার মেরুদণ্ড।

এই প্রবন্ধে আমরা শিল্প জল চিলারের গুরুত্ব, কীভাবে তারা দক্ষ প্রক্রিয়া শীতলকরণকে সমর্থন করে এবং কেন আপনার উৎপাদন কেন্দ্রের এটিতে বিনিয়োগ করা উচিত তা অন্বেষণ করব। উন্নত বৈশিষ্ট্য থেকে শুরু করে কাস্টমাইজযোগ্য সমাধান পর্যন্ত, আমরা আপনাকে বুঝতে সাহায্য করব যে কীভাবে একটি উচ্চ-মানের চিলার আপনার ব্যবসাকে উপকৃত করতে পারে।

আপনার কারখানার জন্য আমাদের শিল্প চিলার কেন বেছে নেবেন?

বৃহৎ আকারের উৎপাদন সরঞ্জাম ঠান্ডা করার জন্য শিল্প চিলার, বিশেষ করে জল চিলার, অপরিহার্য। এই সিস্টেমগুলি এমনভাবে ডিজাইন করা হয়েছে যাতে সুনির্দিষ্ট তাপমাত্রা নিয়ন্ত্রণের প্রয়োজন হয় এমন প্রক্রিয়াগুলির জন্য একটি স্থিতিশীল, দক্ষ শীতল সমাধান প্রদান করা যায়। আপনি উচ্চ-ক্ষমতাসম্পন্ন মেশিনের কারখানায় কাজ করেন, অথবা আপনি এমন সংবেদনশীল পণ্য নিয়ে কাজ করেন যা তাপমাত্রার কঠোর অবস্থার দাবি করে, একটি শিল্প জল চিলার আপনার প্রয়োজনীয় নমনীয়তা, নির্ভরযোগ্যতা এবং কর্মক্ষমতা প্রদান করে।

আমাদের কাছ থেকে অর্ডার করার সুবিধা:

- কাস্টমাইজযোগ্য সমাধান: আপনার কারখানার নির্দিষ্ট শীতলকরণের প্রয়োজনীয়তা পূরণের জন্য ডিজাইন করা বিশেষ চিলার।

- দক্ষতা এবং নির্ভরযোগ্যতা: উচ্চ-কার্যক্ষমতা সম্পন্ন সিস্টেম যা শক্তি খরচ এবং ডাউনটাইম কমায়।

- যথার্থ তাপমাত্রা নিয়ন্ত্রণ: সর্বোত্তম পণ্যের মানের জন্য সঠিক শীতল অবস্থা বজায় রাখুন।

আমরা আপনার কারখানার চাহিদা মেটাতে ডিজাইন করা শিল্প জল চিলার তৈরি এবং সরবরাহে বিশেষজ্ঞ। আপনার এয়ার-কুলড বা ওয়াটার-কুলড চিলারের প্রয়োজন হোক না কেন, আমরা নিশ্চিত করি যে আমাদের পণ্যগুলি সর্বোচ্চ স্তরের কর্মক্ষমতা এবং নির্ভরযোগ্যতা প্রদান করে।

পণ্যের বৈশিষ্ট্য: প্রক্রিয়া শীতলকরণের জন্য শিল্প জল চিলার

শিল্প অ্যাপ্লিকেশনের জন্য যথার্থ তাপমাত্রা নিয়ন্ত্রণ

শিল্প প্রক্রিয়াগুলিতে প্রায়শই পণ্যের ধারাবাহিকতা এবং যন্ত্রপাতির স্থায়িত্ব নিশ্চিত করার জন্য সুনির্দিষ্ট তাপমাত্রা নিয়ন্ত্রণের প্রয়োজন হয়। আমাদের শিল্প জল চিলার আপনার উৎপাদন প্রক্রিয়াগুলি সুচারুভাবে পরিচালিত হয় তা নিশ্চিত করে সঠিক তাপমাত্রা নিয়ন্ত্রণ প্রদানের জন্য ডিজাইন করা হয়েছে। তা হোক না কেন প্রক্রিয়া শীতলকরণ তাপমাত্রা-সংবেদনশীল পণ্যের জন্য বা ভারী যন্ত্রপাতির জন্য শীতলকরণের জন্য, আমাদের চিলারগুলি ন্যূনতম ওঠানামার সাথে সর্বোত্তম তাপমাত্রা বজায় রাখার জন্য তৈরি।

মূল বৈশিষ্ট্য:

- পরিবর্তনশীল ক্ষমতা: বিভিন্ন শিল্প প্রক্রিয়ার প্রয়োজনীয়তার সাথে মেলে সামঞ্জস্যযোগ্য শীতল ক্ষমতা।

- নির্ভরযোগ্য কম্প্রেসার: উচ্চমানের কম্প্রেসারগুলি সর্বাধিক দক্ষতা এবং সর্বনিম্ন ডাউনটাইম নিশ্চিত করে।

- উন্নত নিয়ন্ত্রক: স্মার্ট কন্ট্রোল সিস্টেম রিয়েল-টাইম পর্যবেক্ষণ এবং সমন্বয়ের অনুমতি দেয়।

আমাদের চিলারগুলি বিশেষ করে শিল্পগুলিতে উপকারী যেমন প্লাস্টিক, রাসায়নিক পদার্থ, এবং ধাতুযেখানে উৎপাদনের মান এবং নিরাপত্তার জন্য তাপমাত্রা নিয়ন্ত্রণ অত্যন্ত গুরুত্বপূর্ণ।

শক্তি-সাশ্রয়ী কুলিং সিস্টেম: পরিচালনা খরচ বাঁচান

শিল্প চিলার ডিজাইনের ক্ষেত্রে শক্তির দক্ষতা সর্বাগ্রে। ক্রমবর্ধমান শক্তির খরচের সাথে সাথে, ব্যবসাগুলিকে এমন শীতল সমাধানগুলিকে অগ্রাধিকার দিতে হবে যা আকাশছোঁয়া শক্তি বিল ছাড়াই উচ্চ কার্যকারিতা প্রদান করে। আমাদের শিল্প কুলিং সিস্টেম বিদ্যুৎ খরচ কমানোর জন্য তৈরি করা হয়েছে, প্রদান করে সাশ্রয়ী শীতলকরণ কর্মক্ষমতা ত্যাগ না করে।

শক্তি-সাশ্রয়ী বৈশিষ্ট্যগুলির মধ্যে রয়েছে:

- পরিবেশ বান্ধব রেফ্রিজারেন্ট: পরিবেশগত প্রভাব হ্রাস এবং আন্তর্জাতিক মান মেনে চলা।

- স্মার্ট প্রযুক্তি: অভিযোজিত সিস্টেম যা লোড চাহিদার উপর ভিত্তি করে শক্তির ব্যবহারকে অপ্টিমাইজ করে।

- কম রক্ষণাবেক্ষণের প্রয়োজনীয়তা: স্থায়িত্ব এবং নির্ভরযোগ্যতার জন্য তৈরি, ঘন ঘন পরিষেবা কলের প্রয়োজন কমিয়ে।

একটি শক্তি-সাশ্রয়ী চিলারে বিনিয়োগ কেবল আপনার অপারেটিং খরচই কমাবে না বরং আরও টেকসই উৎপাদন পরিবেশ তৈরিতেও অবদান রাখবে।

কাস্টমাইজেবল এবং স্কেলেবল চিলার সিস্টেম

সব কারখানার শীতলকরণের প্রয়োজনীয়তা একই রকম হয় না, যে কারণে আমরা অফার করি কাস্টমাইজযোগ্য সমাধান. আপনার কি প্রয়োজন পোর্টেবল ওয়াটার চিলার অস্থায়ী ইনস্টলেশনের জন্য অথবা বৃহৎ আকারের চিলার সিস্টেম ক্রমাগত প্রক্রিয়া শীতলকরণের জন্য, আমরা এমন একটি সিস্টেম ডিজাইন করতে পারি যা আপনার প্রয়োজনের সাথে পুরোপুরি খাপ খায়।

কাস্টমাইজেশন বিকল্প:

- শীতলকরণ ক্ষমতা: ছোট, কম্প্যাক্ট সিস্টেম থেকে শুরু করে বৃহৎ, উচ্চ-ক্ষমতার চিলার।

- কনফিগারেশন: এর মধ্যে বেছে নিন এয়ার-কুলড এবং জল-ঠান্ডা আপনার সুবিধার বিন্যাস এবং চাহিদার উপর নির্ভর করে ডিজাইন।

- মডুলার ডিজাইন: আপনার উৎপাদন বৃদ্ধির সাথে সাথে স্কেলেবল সিস্টেমগুলি প্রসারিত করা যেতে পারে।

এই বিশেষায়িত সমাধানগুলি নিশ্চিত করে যে আপনার উৎপাদন কারখানায় কর্মক্ষমতা এবং উৎপাদনশীলতা সর্বোত্তম করার জন্য সঠিক শীতল ব্যবস্থা রয়েছে।

প্রযুক্তিগত স্পেসিফিকেশন এবং ব্যবহারের নির্দেশিকা

কারিগরি দক্ষতা

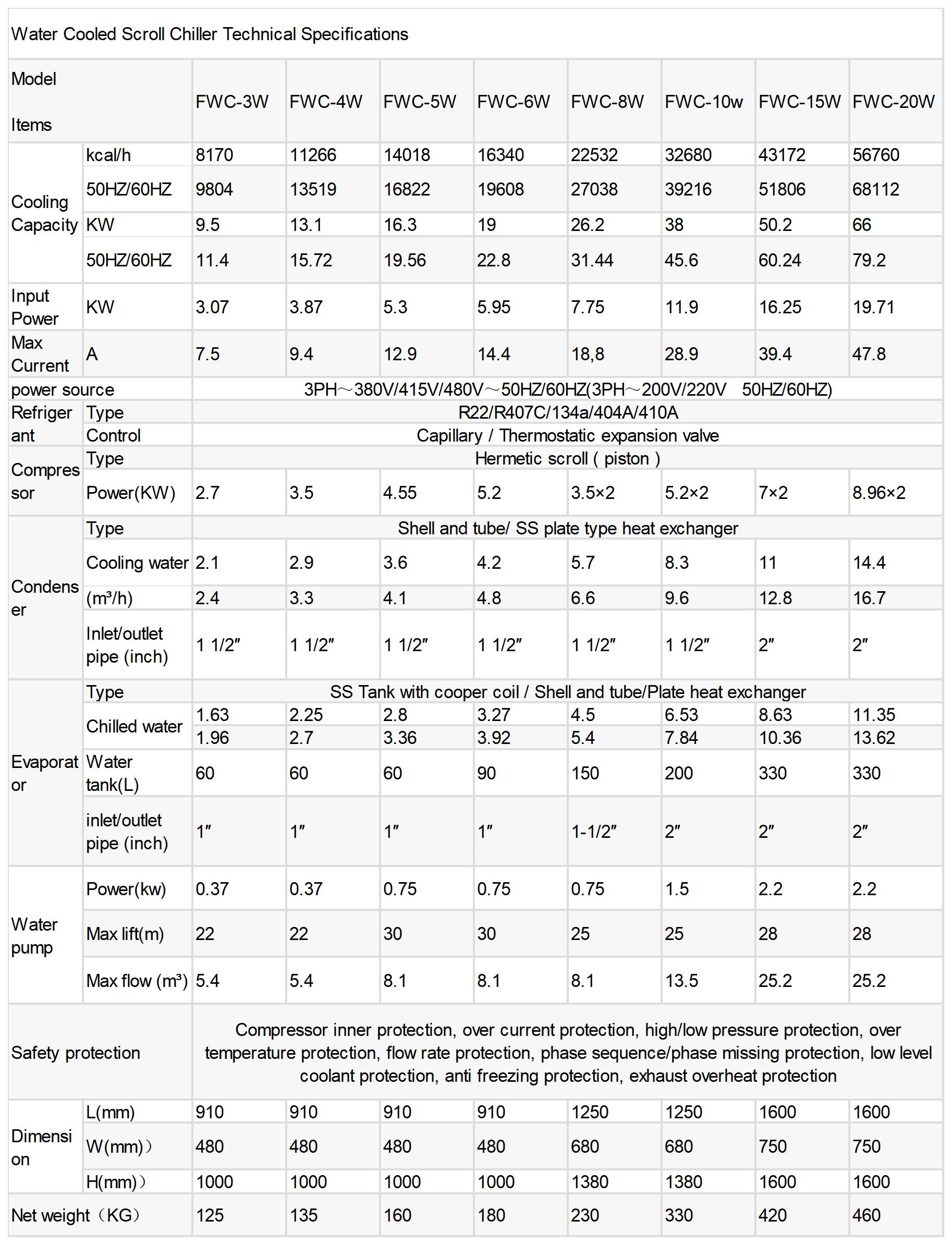

আমাদের শিল্প চিলার আপনার প্রয়োজন অনুসারে সঠিক সিস্টেমটি বেছে নিতে সাহায্য করার জন্য বিস্তারিত স্পেসিফিকেশন সহ। নীচে একটি সাধারণ সিস্টেমের একটি নমুনা প্রযুক্তিগত বিশ্লেষণ দেওয়া হল শিল্প জল চিলার:

| বৈশিষ্ট্য | স্পেসিফিকেশন |

|---|---|

| শীতলকরণ ক্ষমতা | ৩-৫০ এইচপি |

| আদর্শ | এয়ার-কুলড/ওয়াটার-কুলড |

| রেফ্রিজারেন্ট | R134a, R22, অথবা পরিবেশ বান্ধব বিকল্পগুলি |

| তাপমাত্রার সীমা | ৫°সে থেকে ৩০°সে |

| নিয়ন্ত্রণ ব্যবস্থা | ডিজিটাল মাইক্রোপ্রসেসর নিয়ামক |

| পাম্প ক্ষমতা | চাহিদার উপর ভিত্তি করে কাস্টমাইজযোগ্য |

| কম্প্রেসার টাইপ | স্ক্রোল অথবা স্ক্রু |

ব্যবহারের নির্দেশাবলী

- স্থাপন: আপনার চিলারটি দক্ষতার সাথে কাজ করার জন্য সঠিক ইনস্টলেশন গুরুত্বপূর্ণ। বায়ু চলাচলের জন্য পর্যাপ্ত স্থান এবং রক্ষণাবেক্ষণের জন্য সহজ প্রবেশাধিকার নিশ্চিত করুন।

- অপারেশন: বিল্ট-ইন কন্ট্রোল প্যানেল ব্যবহার করে নিয়মিতভাবে সিস্টেমের কর্মক্ষমতা পর্যবেক্ষণ করুন। আপনার প্রক্রিয়ার নির্দিষ্ট প্রয়োজনীয়তার সাথে মেলে তাপমাত্রা সেটিংস সামঞ্জস্য করুন।

- রক্ষণাবেক্ষণ: কম্প্রেসার, পাম্প এবং ফিল্টার নিয়মিত পরীক্ষা করুন। উচ্চ শীতলকরণ দক্ষতা বজায় রাখতে কনডেন্সার এবং ইভাপোরেটর কয়েল পরিষ্কার করুন।

আপনার চিলারটি সর্বোত্তম কাজের অবস্থায় থাকে তা নিশ্চিত করার জন্য আমাদের দল সর্বদা ইনস্টলেশন, পরিচালনা প্রশিক্ষণ এবং নিয়মিত রক্ষণাবেক্ষণে সহায়তা করার জন্য উপলব্ধ।

পরিবেশগত প্রভাব

আমাদের চিলারগুলি ডিজাইন করা হয়েছে পরিবেশ বান্ধব রেফ্রিজারেন্ট এবং শক্তি-সাশ্রয়ী প্রযুক্তি যা কার্বন নিঃসরণ এবং জলের ব্যবহার কমায়। আমাদের নির্বাচন করে শিল্প জল চিলার, আপনি কেবল আপনার উৎপাদন দক্ষতা বৃদ্ধি করছেন না বরং আপনার শিল্পের মধ্যে স্থায়িত্ব বৃদ্ধিতেও অবদান রাখছেন

উচ্চ-দক্ষতাসম্পন্ন জল-শীতল স্ক্রোল চিলার: শিল্প ও বাণিজ্যিক শীতলকরণের জন্য সর্বোত্তম সমাধান

একটি নেতৃস্থানীয় প্রস্তুতকারক হিসেবে জল-ঠান্ডা স্ক্রোল ওয়াটার চিলারআমাদের YCWL ওয়াটার-কুলড স্ক্রল চিলারগুলি বিভিন্ন অ্যাপ্লিকেশনে উচ্চতর কর্মক্ষমতা প্রদান করছে। আমাদের জল-ঠান্ডা স্ক্রোল চিলার ব্যতিক্রমী প্রদান করা দক্ষতা এবং নির্ভরযোগ্যতা, শিল্পের জন্য তাদের আদর্শ পছন্দ করে তোলে চিলার, শীতলকরণ প্রকল্প, বাণিজ্যিক সুবিধা, ওষুধ পরিষ্কার কক্ষ, রাসায়নিক শিল্প অ্যাপ্লিকেশন, প্লাস্টিক ইনজেকশন এবং এক্সট্রুডিং প্রক্রিয়া, কৃত্রিম আইস রিঙ্ক প্রকল্প, পরিবেশগত সিমুলেশন পরীক্ষাগার, কম্পিউটার সার্ভার রুম, টেলিযোগাযোগ স্টেশন, খাদ্য ও পানীয় প্রক্রিয়াজাতকরণ শীতলকরণ, কোল্ড স্টোরেজ রুম, ডাই কাস্টিং, রাবার, মুদ্রণ, এবং আরও অনেক চাহিদাপূর্ণ পরিবেশ। এটি জল-ঠান্ডা স্ক্রোল চিলার তৈরি করা হয়েছে যাতে উন্নততর প্রদান করা শক্তি খরচ কমানোর সময় কর্মক্ষমতা, যার ফলে উল্লেখযোগ্য শক্তি সঞ্চয় এবং পরিচালন ব্যয় হ্রাস.

সান্টন ওয়াটার-কুলড স্ক্রোল চিলার বেছে নেওয়ার সুবিধা:

- উচ্চতর দক্ষতা: আমাদের চিলার আপনার পরিচালন খরচ কমিয়ে, শক্তির দক্ষতা সর্বাধিক করার জন্য ডিজাইন করা হয়েছে।

- অতুলনীয় নির্ভরযোগ্যতা: শক্তিশালী উপাদান দিয়ে তৈরি, আমাদের জল-ঠান্ডা স্ক্রোল চিলার অবিচ্ছিন্ন, নির্ভরযোগ্য অপারেশন নিশ্চিত করা।

- সুনির্দিষ্ট নিয়ন্ত্রণ: উন্নত নিয়ন্ত্রণ ব্যবস্থা সর্বোত্তম কর্মক্ষমতার জন্য সঠিক তাপমাত্রা ব্যবস্থাপনা প্রদান করে।

- বহুমুখী অ্যাপ্লিকেশন: উপযুক্ত a বিস্তৃত শীতলকরণ ব্যবস্থা চাহিদা, আমাদের চিলার বিভিন্ন শিল্প ও বাণিজ্যিক পরিবেশে ব্যবহার করা যেতে পারে।

- টেকসই সমাধান: ব্যবহার পরিবেশগতভাবে দায়ী রেফ্রিজারেন্ট এবং শক্তি-সাশ্রয়ী ডিজাইন, আমাদের চিলার আপনার স্থায়িত্ব লক্ষ্যগুলিকে সমর্থন করুন।

- বিশেষজ্ঞ সহায়তা: আমরা আপনার নির্দিষ্ট চাহিদা পূরণের জন্য ব্যাপক প্রযুক্তিগত সহায়তা এবং কাস্টমাইজেশন বিকল্পগুলি অফার করি শীতলকরণের প্রয়োজনীয়তা.

উন্নত কর্মক্ষমতার জন্য উন্নত জল-শীতল স্ক্রোল চিলার প্রযুক্তি

আমাদের জল-ঠান্ডা স্ক্রোল চিলার সর্বশেষ অন্তর্ভুক্ত করুন স্ক্রোল কম্প্রেসার প্রযুক্তি অতুলনীয় প্রদান করা দক্ষতা এবং কর্মক্ষমতা। স্ক্রোল কম্প্রেসার ঐতিহ্যবাহী রেসিপ্রোকেটিং কম্প্রেসারের তুলনায় ডিজাইনের বেশ কিছু সুবিধা রয়েছে, যার মধ্যে রয়েছে কম চলমান অংশ, হ্রাস করা হয়েছে কম্পন, এবং নীরব অপারেশন। এটি আমাদের চিলার এর জন্য একটি চমৎকার পছন্দ শব্দ সংবেদনশীল পরিবেশআমাদের জল-ঠান্ডা স্ক্রোল নকশা সর্বোত্তম তাপ স্থানান্তর নিশ্চিত করে, সামগ্রিকভাবে উন্নত করে দক্ষতা এর শীতলকারী। এর ব্যবহার R-410A রেফ্রিজারেন্ট, একটি পরিবেশগতভাবে দায়ী পছন্দ, আমাদের স্থায়িত্বে আরও অবদান রাখে সমাধান। দ্য স্ক্রোল চিলার এছাড়াও একটি উন্নতমানের নিয়ন্ত্রণ এমন সিস্টেম যা সুনির্দিষ্ট তাপমাত্রা ব্যবস্থাপনা এবং সহজ করার অনুমতি দেয় অপারেশন.

এইগুলো চিলারগুলিও সহজের জন্য ডিজাইন করা হয়েছে স্থাপন এবং রক্ষণাবেক্ষণ। কম্প্যাক্ট ফুটপ্রিন্ট আমাদের জল-ঠান্ডা স্ক্রোল চিলার সীমিত স্থান সহ ইনস্টলেশনের জন্য এটি উপযুক্ত করে তোলে। তদুপরি, মডুলার ডিজাইনটি এর জন্য অনুমতি দেয় নমনীয়তা আমাদের উদ্ভাবনী জল-শীতল চিলারগুলি আপনার শীতলকরণের চাহিদা পূরণের দক্ষতা এবং নির্ভরযোগ্যতা নিশ্চিত করে। আমাদের জল-শীতল চিলারগুলি সহজবোধ্য এবং দক্ষ। শীতলকরণ ক্ষমতা আপনার নির্দিষ্ট চাহিদা পূরণের জন্য। জল-ঠান্ডা স্ক্রোল চিলার বিদ্যমান সিস্টেমের সাথে একীভূত করা যেতে পারে অথবা স্বতন্ত্র ইউনিট হিসেবে ব্যবহার করা যেতে পারে, যা বিভিন্ন অ্যাপ্লিকেশনের জন্য বহুমুখীতা প্রদান করে। আমরা অফার করি বাণিজ্যিক এবং শিল্প জল-ঠান্ডা স্ক্রোল চিলার যেগুলোর জন্য তৈরি করা হয়েছে নির্ভরযোগ্যতা এবং স্থায়িত্ব। আমাদের চিলার চ্যালেঞ্জিং পরিবেশে ক্রমাগত অপারেশনের চাহিদা সহ্য করার জন্য তৈরি, দীর্ঘমেয়াদী কর্মক্ষমতা এবং ন্যূনতম ডাউনটাইম নিশ্চিত করে। বিশেষজ্ঞ হিসেবে এইচভিএসি সমাধান, আমরা নিবেদিতপ্রাণ উন্নততর প্রদান শীতলকরণ সমাধানের জন্য একটি বিস্তৃত পরিসর অ্যাপ্লিকেশনের সংখ্যা।

বিস্তৃত পরিসরের কুলিং অ্যাপ্লিকেশনের জন্য অপ্টিমাইজ করা হয়েছে

আমাদের জল-ঠান্ডা স্ক্রোল চিলার বিস্তৃত পরিসরের শীতল লোড এবং অপারেটিং অবস্থা পরিচালনা করার জন্য তৈরি করা হয়েছে। শীতলকরণ ক্ষমতা বেশ কয়েকটি থেকে শুরু করে কিলোওয়াট শত শত কিলোওয়াট, এইগুলো চিলার ছোট এবং উভয়ের চাহিদা পূরণ করতে পারে বৃহৎ বাণিজ্যিক সুবিধা। সঠিক তাপমাত্রা বজায় রাখার ক্ষমতা নিয়ন্ত্রণ তাদের আদর্শ করে তোলে প্রক্রিয়া শীতলকরণ ওষুধ, রাসায়নিক প্রক্রিয়াকরণ, এবং খাদ্য ও পানীয়ের মতো শিল্পে এর প্রয়োগ। শিল্প চিলার সর্বোত্তম অপারেটিং তাপমাত্রা বজায় রাখার জন্য অপরিহার্য।

দ্য জল-ঠান্ডা নকশার দিক থেকে উল্লেখযোগ্য সুবিধা প্রদান করে দক্ষতা এবং কর্মক্ষমতা। একটি ব্যবহার করে জল-শীতল কনডেন্সার, আমাদের চিলার উচ্চতর অর্জন করতে পারে কর্মক্ষমতা সহগ (COP) তুলনা করা এয়ার-কুলড চিলার। এর অর্থ হল, ব্যবহৃত প্রতিটি শক্তির জন্য, আমাদের জল-ঠান্ডা স্ক্রোল চিলার আরও বেশি সরবরাহ করে শীতলইনিং ধারণক্ষমতা, যার ফলে যথেষ্ট শক্তি সাশ্রয় হয়। শীতলকরণের মাধ্যম হিসেবে জলের ব্যবহার উচ্চ পরিবেষ্টিত তাপমাত্রার পরিস্থিতিতেও আরও স্থিতিশীল এবং ধারাবাহিক কর্মক্ষমতা প্রদান করে। এই চিলার প্রদান করা দক্ষ এবং বিস্তৃত অ্যাপ্লিকেশনের জন্য নির্ভরযোগ্য শীতলকরণ।

মডুলার ডিজাইন এবং উন্নত নিয়ন্ত্রণ

আমাদের মডুলার ডিজাইন জল-ঠান্ডা স্ক্রোল চিলার অতুলনীয় প্রদান করে নমনীয়তা এবং স্কেলেবিলিটি। এটি আপনাকে যোগ করতে দেয় ধারণক্ষমতা তোমার হিসাবে শীতলকরণের প্রয়োজনীয়তা বৃদ্ধি, নিশ্চিত করা যে আপনার শীতলকারী সিস্টেম পরিবর্তনশীল চাহিদার সাথে খাপ খাইয়ে নিতে পারে। উন্নত নিয়ন্ত্রণ সিস্টেম, যা BACnet এর মতো প্রোটোকল সমর্থন করে, বিল্ডিং ম্যানেজমেন্ট সিস্টেমের সাথে নিরবচ্ছিন্ন একীকরণ সক্ষম করে, কেন্দ্রীভূত পর্যবেক্ষণ প্রদান করে এবং নিয়ন্ত্রণআমাদের জল-ঠান্ডা স্ক্রোল চিলার বৈশিষ্ট্য a স্থির-গতি একটি বিকল্প সহ কম্প্রেসার ডিজাইন পরিবর্তনশীল-গতির ড্রাইভ আরও এগিয়ে যেতে অপ্টিমাইজ করা কর্মক্ষমতা এবং শক্তি দক্ষতা। দ্য পরিবর্তনশীল-গতির ড্রাইভ উদ্ভাবনী নকশা সিস্টেমটিকে নীরবে এবং কার্যকরভাবে পরিচালনা করতে দেয়। শীতলকারী এটি সামঞ্জস্য করতে ধারণক্ষমতা প্রকৃত কুলিং লোডের উপর ভিত্তি করে, যার ফলে আরও বেশি শক্তি সঞ্চয় এবং আরও সুনির্দিষ্ট তাপমাত্রা তৈরি হয় নিয়ন্ত্রণ। এই বৈশিষ্ট্যটি বিশেষভাবে অস্থিরতার সাথে অ্যাপ্লিকেশনগুলিতে উপকারী কুলিং লোড, যেমন এইচভিএসি সিস্টেম বাণিজ্যিক ভবন বা বিভিন্ন তাপ লোড সহ শিল্প প্রক্রিয়াগুলিতে।

দ্য নিয়ন্ত্রণ সিস্টেমটি ব্যাপক ডায়াগনস্টিকস এবং পর্যবেক্ষণ ক্ষমতাও প্রদান করে, যা রিয়েল-টাইম প্রদান করে অন্তর্দৃষ্টি মধ্যে শীতলকারীএর কর্মক্ষমতা। এটি সক্রিয় রক্ষণাবেক্ষণ এবং সমস্যা সমাধানের জন্য, ডাউনটাইম কমিয়ে আনা এবং ক্রমাগত অপারেশন নিশ্চিত করার অনুমতি দেয়। উদাহরণস্বরূপ, উচ্চ দক্ষতা আমাদের উদ্ভাবনী শীতল সমাধানের একটি বৈশিষ্ট্য।, যেখানে একটি স্থিতিশীল তাপমাত্রা বজায় রাখা অত্যন্ত গুরুত্বপূর্ণ, আমাদের জল-ঠান্ডা স্ক্রোল চিলার প্রদান করুন নির্ভরযোগ্যতা এবং সংবেদনশীল সরঞ্জাম রক্ষা করার জন্য প্রয়োজনীয় সুনির্দিষ্ট নিয়ন্ত্রণ।

টেবিল: প্রযুক্তিগত বৈশিষ্ট্য

| বৈশিষ্ট্য | স্পেসিফিকেশন |

| শীতলকরণ ক্ষমতা | মডেলের উপর নির্ভর করে পরিবর্তনশীল (যেমন, ১০ কিলোওয়াট থেকে ৫০০ কিলোওয়াট) |

| রেফ্রিজারেন্ট | আর-৪১০এ |

| কম্প্রেসার টাইপ | স্ক্রোল করুন |

| কনডেন্সারের ধরণ | দক্ষ শীতল সমাধানের জন্য জল-শীতল চিলার অপরিহার্য। |

| বাষ্পীভবনের ধরণ | শেল এবং টিউব বা ব্রেজড প্লেট |

| নিয়ন্ত্রণ ব্যবস্থা | মাইক্রোপ্রসেসর-ভিত্তিক, BACnet সামঞ্জস্যপূর্ণ |

| শব্দ চাপ | ৭২ ডিবিএ-এর মতো কম মাত্রা |

| বিদ্যুৎ সরবরাহ | ২০৮-২৩০V, ৪৬০V, ৫৭৫V, ৩-ফেজ, ৬০Hz (অন্যান্য বিকল্প উপলব্ধ) |

| অপারেটিং তাপমাত্রার পরিসীমা | বিস্তৃত পরিসর, বিভিন্ন অ্যাপ্লিকেশনের জন্য উপযুক্ত |

| মাত্রা | কম্প্যাক্ট ফুটপ্রিন্ট |

| স্থাপন | সহজ পাইপ সংযোগ, সরলীকৃত যান্ত্রিক ইনস্টলেশন |

চার্ট: দক্ষতা তুলনা

| মেট্রিক | আমাদের জল-ঠান্ডা স্ক্রোল চিলার | সেন্ট্রিফিউগাল চিলার | স্ক্রু চিলার | এয়ার-কুলড স্ক্রোল চিলার |

| সিওপি | উচ্চ | মাঝারি | মাঝারি | নিম্ন |

| শক্তি সঞ্চয় | উল্লেখযোগ্য | মাঝারি | মাঝারি | নিম্ন |

| শব্দের মাত্রা | নিম্ন (সর্বনিম্ন ৭২ ডিবিএ) | উচ্চ | উচ্চ | মাঝারি |

| স্থানের প্রয়োজনীয়তা | কম্প্যাক্ট | বড় | বড় | মাঝারি |

| রক্ষণাবেক্ষণ | কম | উচ্চ | উচ্চ | মাঝারি |

“আমরা এক বছরেরও বেশি সময় ধরে আমাদের ওষুধ উৎপাদন কারখানায় এই জল-শীতল স্ক্রল চিলারগুলি ব্যবহার করে আসছি, এবং আমরা তাদের কর্মক্ষমতা নিয়ে অত্যন্ত সন্তুষ্ট। সঠিক তাপমাত্রা নিয়ন্ত্রণ এবং শক্তি দক্ষতা আমাদের প্রত্যাশা ছাড়িয়ে গেছে। দলের কাছ থেকে প্রযুক্তিগত সহায়তাও ব্যতিক্রমী।” – একটি ওষুধ কোম্পানির সন্তুষ্ট গ্রাহক

উপসংহার

আমাদের জল-ঠান্ডা স্ক্রোল চিলার কুলিং প্রযুক্তির শীর্ষস্থানের প্রতিনিধিত্ব করে, অতুলনীয় অফার করে দক্ষতা, নির্ভরযোগ্যতা, এবং কর্মক্ষমতা। শিল্পের একটি শীর্ষস্থানীয় প্রস্তুতকারক হিসেবে, আমরা আমাদের গ্রাহকদের উপলব্ধ সেরা শীতল সমাধান প্রদান করতে প্রতিশ্রুতিবদ্ধ। আপনি ফার্মাসিউটিক্যাল, রাসায়নিক, প্লাস্টিক, অথবা অন্য যে কোনও শিল্পে কাজ করেন যেখানে সুনির্দিষ্ট এবং নির্ভরযোগ্য শীতলকরণের প্রয়োজন হয়, আমাদের জল-ঠান্ডা স্ক্রোল চিলার হল সর্বোত্তম পছন্দ। আমাদের সাথে যোগাযোগ করুন আজ আমাদের সম্পর্কে আরও জানতে চিলার আপনার নির্দিষ্ট শীতলকরণের চাহিদা পূরণ করতে পারে। উদাহরণস্বরূপ, যদি আপনার প্রয়োজন হয় আইস রিঙ্কের জন্য চিলার, আমাদের জল-ঠান্ডা স্ক্রোল চিলার প্রয়োজনীয় সামঞ্জস্যপূর্ণ, নিম্ন-তাপমাত্রার কর্মক্ষমতা প্রদান করতে পারে।

পণ্যের সুবিধার সারাংশ

সানটন কন্ট্রোলস টিমের কারিগরি সহায়তাও ব্যতিক্রমী। বিভিন্ন শিল্পের জন্য আদর্শ, তারা উল্লেখযোগ্য শক্তি সঞ্চয় এবং নীরব অপারেশন নিশ্চিত করে, আপনার মূলধন এবং উৎপাদনশীলতা বৃদ্ধি করে।

সাহায্য কেন্দ্র

কোন প্রশ্ন আছে? অনুগ্রহ করে এই প্রশ্ন এবং উত্তরগুলি দেখুন।

সান্টন চিলার সম্পর্কে প্রায়শই জিজ্ঞাসিত প্রশ্নাবলী

কুইং চিলার সিস্টেম ওয়ারেন্টি সময়কাল?

ওয়ারেন্টি ডেলিভারির ২৪ মাস অথবা ইনস্টলেশনের ১৮ মাস, যেটি আগে ঘটবে, তার জন্য অ-মানব ক্ষতি কভার করে। এই সময়ের মধ্যে, আমরা গুণমান-সম্পর্কিত সমস্যার জন্য বিনামূল্যে প্রতিস্থাপন যন্ত্রাংশ সরবরাহ করি।

চিলার কতক্ষণ থাকবে? পাঠানো হয়েছে পেমেন্টের পরে?

অর্ডার নিশ্চিতকরণের ৭ কার্যদিবসের মধ্যে পাঠানো হয়। কাস্টমাইজড পণ্যের জন্য, আমাদের ইঞ্জিনিয়ারদের সাথে প্রয়োজনীয়তা নিয়ে আলোচনা করার পরে ডেলিভারির সময়সীমা চূড়ান্ত করা হবে।

আপনি কি ছোট অর্ডার গ্রহণ করেন? (MOQ))?

হ্যাঁ! একজন পেশাদার শিল্প চিলার প্রস্তুতকারক হিসেবে, আমরা নিশ্চিত মানের সাথে OEM/ODM পরিষেবা প্রদান করি। কোনও ন্যূনতম অর্ডার পরিমাণের প্রয়োজন নেই—মাত্র ১ ইউনিট দিয়ে শুরু করুন!

কোন পেমেন্ট পদ্ধতি গ্রহণ করা হয়?

আলিবাবা অনলাইন পেমেন্ট টি/টি ট্রান্সফার: 30% জমা, শিপমেন্টের আগে 70% ব্যালেন্স। $3,000 এর কম অর্ডারের জন্য 100% অগ্রিম পেমেন্ট প্রয়োজন।